Page 1 of 4

New Slump MOLD

Posted: Fri Dec 13, 2013 7:47 pm

by twin vision glass

- phpWMdL1NPM.jpg (35.89 KiB) Viewed 24520 times

I purchased a new slump Mold from Laurie Spray and I simply LOVE it. So thank you so much Laurie. Now off I go to slump more pieces. Les

Re: New Slump MOLD

Posted: Fri Dec 13, 2013 7:53 pm

by twin vision glass

- phpuIMnzBPM (1).jpg (36.91 KiB) Viewed 24519 times

Oh I forgot to post the panel part also . BUT now I am going to slump the large panel as well, it is 32 inchs x 19 inchs and it is an experiment to see if my kiln will handle it.

Hmmmm!!!!!!!! Les

Re: New Slump MOLD

Posted: Fri Dec 13, 2013 9:30 pm

by Laurie Spray

Les,

I am so glad the papa drop ring not only got to you safely but that you are so happy with it!! This 22" is the largest drop ring I have made so far. Look at the prototypes I have coming for 2014! (under "Other Molds, then Prototype ideas) We would love feedback on these ideas! I would love you especially to look at #3!

Love the colors in this piece!!!!!

Re: New Slump MOLD

Posted: Tue Dec 17, 2013 12:02 am

by twin vision glass

Well I have decided to practice a slump with the large 32 inch panel in behind this bowl. I have to do 3 large 32 inch by 19 inch by 6 inch deep slumps and well, my kiln might be just abit small but am trying it anyways. It is in the center of the kiln with top and bottom fire, BUT close to sides . Only 4 inchs away on each side. My problem might be at the corners. Will keep you all posted for sure. Les

Re: New Slump MOLD

Posted: Tue Dec 17, 2013 3:37 pm

by twin vision glass

- phpLxmomNAM.jpg (36.67 KiB) Viewed 24335 times

Here is the start of my new 3 large vessel's that will span 9 feet. Exciting. Les

Re: New Slump MOLD

Posted: Tue Dec 17, 2013 9:03 pm

by twin vision glass

Well so far the slump looked really good so now we waite.

Re: New Slump MOLD

Posted: Fri Dec 20, 2013 6:14 pm

by twin vision glass

Large deep slump panel comes out tomorrow and this piece is ready to go in and has 3 large panels that will all be slumped like the Dense white/ French Vanilla / Opaline / and pulled canes from hot shop.

- phpYhjEqQPM.jpg (34.06 KiB) Viewed 24176 times

Re: New Slump MOLD

Posted: Sat Dec 21, 2013 12:50 pm

by twin vision glass

- phptJPlmmAM.jpg (35.28 KiB) Viewed 24128 times

- phpSP2X18AM.jpg (34.14 KiB) Viewed 24128 times

Well we are what our equipment is. Oh so darnit. BUT it is still workable and Rick Wilton is helping me with some polishing bless him. With my kiln being just to small ;pieces that I want to try I just should not anyways, and should know better, but just have TO TRY anyways, to break the piece when I should not have tried in my kiln. How is that for a sentence. BUT it is in 2 pieces now and still will be a lovely bowl when my metal worker extraodinaire gets finished. So keep posted for the final piece. Ughhh but not let down yet.

Les

Re: New Slump MOLD

Posted: Sun Dec 22, 2013 12:45 pm

by twin vision glass

Re: New Slump MOLD

Posted: Mon Dec 23, 2013 10:37 pm

by twin vision glass

- phpA36vwHPM.jpg (27.84 KiB) Viewed 24001 times

- phpC0y9XGPM.jpg (27.06 KiB) Viewed 24001 times

Pehaps my lesson is to not give up and try and if you fail , just change things to look like something else and you usually learn something really cool. I will get my metal artist to fabricate a metal stand to join these two pieces and make it better than it was hopefully. I did that to the brown one in the photo and it turned out and I was happy with the challenge. BUT with out Rick Wilton, I would not be able to do things that I truly want as he is my polisher helper for sure and does an extra ordinary job at it so thank you Rick .

Leslie

Re: New Slump MOLD

Posted: Tue Dec 24, 2013 12:54 pm

by twin vision glass

Come February I am excited to be able to go to Uroboros Glass Company for a residency and hope to meet a few of the wonderful artists in Portland. Middle of February turning 60 as well, ughghg , but will not slow me down. So I look so forward to meeting some artists and sharing techniques and stories of their glass journey. Maybe Kat will let us have a get together around the kilns. Hmm! that would be fun.

Leslie

Re: New Slump MOLD

Posted: Thu Dec 26, 2013 2:43 pm

by twin vision glass

- php4STcMDAM.jpg (41.2 KiB) Viewed 23894 times

- phpPj5CFhAM.jpg (37.74 KiB) Viewed 23894 times

Hello to everyone, well so far so good., NOW to slump in a larger kiln that a friend has so graciously let me rent but not till Jan . 6th sooooo! I will fire the other 2 panels before they tooo will be slumped. (one of them perhaps at Uroboros . ) as the glass is Uroboros 90 FX . I am firing the smaller panel now and will slump here.

Leslie

Re: New Slump MOLD

Posted: Sun Dec 29, 2013 1:28 pm

by Sue Hunchuk

Wow! That is quite a kiln full of beauty! Leslie, i am trying to figure out why you say your kiln is too small... Is it that there is no space around the kiln shelf,,,so heated air under the shelf is trapped...and same on top...and therefore your mass of glass is not being heated evenly? Am I making sense?

Re: New Slump MOLD

Posted: Sun Dec 29, 2013 5:22 pm

by twin vision glass

Hi Sue, how are you. The kiln is not wide and long enough. LOTS of room above and below but tooooo close to outer edges. BUT I am making a mold mix 6 slumping mold right now and am renting a friends kiln in early January so will be able to have lots of room around the outer edge. It is a top / side fire which I think will be even better so no where will it heat up unevenly as I will baffle edges tooo. So I have got the MOLD MIX 6 applied now and just hope it does not curl tooo much on outer edge. I am calling it the "PINK ALLIEN" as it is dyed pink on outer layer. Anyways, will try to take a pic for you.

Les

Re: New Slump MOLD

Posted: Sun Dec 29, 2013 5:39 pm

by twin vision glass

Re: New Slump MOLD

Posted: Sun Dec 29, 2013 8:20 pm

by Joe Lorenzino

Greetings Les,

Would it help if you mist the edges with a plant sprayer as it dries?

Might it also help prevent the mold from curling if you turn it over and remove the form so that it can dry from both sides?

A temporary support that is cut out to go around the dome (plywood, or maybe an old card table) with a brace attached to hold the centre in place might work ( I was thinking sort of like flipping a stained glass panel between 2 boards when soldering)

Re: New Slump MOLD

Posted: Sun Dec 29, 2013 8:47 pm

by twin vision glass

Hi Joe, long time since I have heard how you are. Well I do hope. Mold Mix 6 is abit finicky and is very fragile until well dried and fired. BUT good ideas for sure. I am putting long Kiln Dams that are 36 inchs long that will help to keep it from curling so I will let you know how that works. Not sure were to burn (very carefully) the wax out but will figure that out in a few days. I usually do out side but since it it minus 10 C. that might not be an option.

Leslie

Re: New Slump MOLD

Posted: Sun Dec 29, 2013 9:22 pm

by Joe Lorenzino

I don't know if you will have to burn the wax out, as on a form with as much "draft" or clearance as this one, the only thing that will be holding the wax in is likely the toothpicks.

If the toothpicks are there to form vents, some one like me would CAREFULLY trim the MM6 on them down to the surrounding level, then pull ( or maybe drill ) them out of the MM6 to release the wax.

After that, maybe just putting it outside at -10°c might make the wax shrink up enough that it will fall right out.

Re: New Slump MOLD

Posted: Mon Dec 30, 2013 12:29 am

by twin vision glass

- phpwG8pfnPM.jpg (24.22 KiB) Viewed 23718 times

Yes the toothpics have to come out and usually when you gently burn the wax out with a tiger torch the toothpics burn out first leaving a very nice vent. AND well, because of the water in the MM6 it would be not super good if the mold froze and maybe cracked BUT that is a really great idea and I wish I was brave enough to give it a go. All I need is a good garage to burn out though. So I will keep you posted in a few days. I like torching because it cures the MM6 and makes it really strong before even going in the kiln to then go up to 1500 deg. F. and after that PRIME.

Les

Re: New Slump MOLD

Posted: Mon Dec 30, 2013 2:13 pm

by twin vision glass

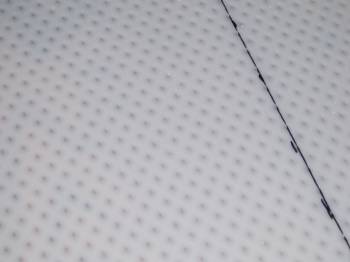

- phpsZUhe8AM.jpg (23.57 KiB) Viewed 23690 times

Perhaps a really interesting thought tooo was to create this large mold on a plastic form that has tiny little indents . My thinking was that it will gently hold the large panel in place while the center slumps down. Sometimes it tends to want to pull the edges inward but this will prevent that and also give air under the glass until ready to slump. Like tiny little hands holding it up off the shelf until slump has occured , helping to not thermal shock the piece.

So fun thinking of new ways to approach things.

Leslie