Quick technical question

Moderators: Brad Walker, Tony Smith

-

twin vision glass

- Posts: 570

- Joined: Thu Apr 29, 2004 12:55 am

- Location: Invermere,B.C. Canada

- Contact:

Quick technical question

Hello! I am creating a large 30 inch by 17 inch by 1 inch thick cast panel that had a sad thing happen today. I have created many of these pieces and well, BC Hydro came by and said they had to turn off the streets power to fix a transformer and I begged them to waite a few days but alas they could not. My kiln was on it's way down and had just annealed and was at 898 deg. F. It dropped 50 deg. in the 10 minutes that the power was out. When it came back on I quickly set a new program to go up to 1100 Deg. F. and then back down to 900 Deg F. to anneal again and start the slow ramp to room temp. Do you think it will be O.K. I am not optimistic but worry even if it does survive, can I chance it going out on the market. What are your resource teams thoughts. I look forward to hearing from the experts and will thankyou from my heart for the information.

Leslie Rowe-Israelson

Leslie Rowe-Israelson

Give out Free Hugs!

website: http://www.twinvision.fusedglassartists.com

website: http://www.twinvision.fusedglassartists.com

-

twin vision glass

- Posts: 570

- Joined: Thu Apr 29, 2004 12:55 am

- Location: Invermere,B.C. Canada

- Contact:

Re: Quick technical question

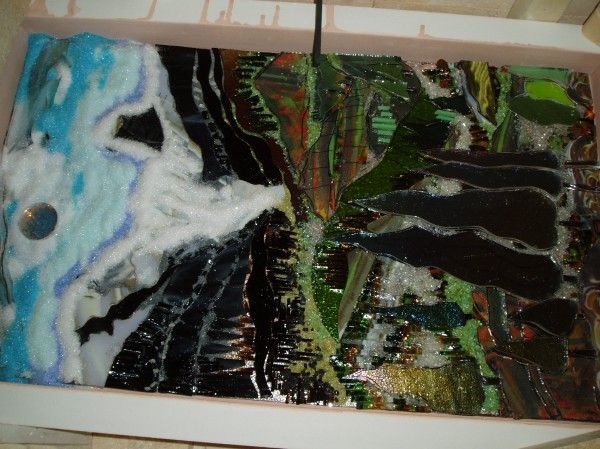

The piece was similiar to this one

Schedule for new anneal is as follows:

Going back up to anneal was:

-30 minutes up from 850. Deg F. to 1100 deg. F. Hold 1 minute

-3 minutes down to 900 Deg. F. Anneal 6 hours

-12 deg. per hour down to 800 F.

-20 deg. per hour down to 700 F.

-50 deg . per hour down to 100. F.

Give out Free Hugs!

website: http://www.twinvision.fusedglassartists.com

website: http://www.twinvision.fusedglassartists.com

-

Brad Walker

- Site Admin

- Posts: 1489

- Joined: Fri Mar 07, 2003 9:33 pm

- Location: North Carolina, USA

- Contact:

Re: Quick technical question

I think it will be ok. Reheating above the annealing range, then re-annealing should work fine.

-

twin vision glass

- Posts: 570

- Joined: Thu Apr 29, 2004 12:55 am

- Location: Invermere,B.C. Canada

- Contact:

Re: Quick technical question

Brad, I respect your expertise and thankyou so much for giving me some insight and alittle peace of mind. I was so sad when the men came to the door and they looked at me as if I was from Mars when I asked if they could come back at a later date.  . Going back above the anneal I think was important. I will keep you posted. It takes so long to make colour bars, slice them and then add all the time and glass.

. Going back above the anneal I think was important. I will keep you posted. It takes so long to make colour bars, slice them and then add all the time and glass.

Leslie

P.S. had a GREAT answer from Ted Sawyer at Bullseye who has an excellent suggestion for anyone else if this happens. Take SLOWER up to 1100 F. so you do not thermal shock the piece. Ughghg ! what was I thinking. I was nervous and hurrying.

Now I have a NEW worry, but I thought I would share so no one else has this problem.

Now I have a NEW worry, but I thought I would share so no one else has this problem.

Leslie

P.S. had a GREAT answer from Ted Sawyer at Bullseye who has an excellent suggestion for anyone else if this happens. Take SLOWER up to 1100 F. so you do not thermal shock the piece. Ughghg ! what was I thinking. I was nervous and hurrying.

Give out Free Hugs!

website: http://www.twinvision.fusedglassartists.com

website: http://www.twinvision.fusedglassartists.com

-

Brad Walker

- Site Admin

- Posts: 1489

- Joined: Fri Mar 07, 2003 9:33 pm

- Location: North Carolina, USA

- Contact:

Re: Quick technical question

If it survived the trip to 1100F without cracking, then you annealed, it won't be a problem.twin vision glass wrote:Take SLOWER up to 1100 F. so you do not thermal shock the piece. Ughghg ! what was I thinking. I was nervous and hurrying.

Now I have a NEW worry, but I thought I would share so no one else has this problem.

-

Kevin Midgley

- Posts: 773

- Joined: Mon Mar 10, 2003 11:36 am

- Location: Tofino, British Columbia, Canada

Re: Quick technical question

Just another thought. I don't know if one of my kilns would drop the 50 degrees in 10 minutes if I had that much thermal mass inside the kiln. I would say that indicates air flow into and out of the kiln. It might be a good time to consider if there are air leaks as that is costing you big time on your energy bill.

-

twin vision glass

- Posts: 570

- Joined: Thu Apr 29, 2004 12:55 am

- Location: Invermere,B.C. Canada

- Contact:

Re: Quick technical question

Thanks Brad for sure and YES Kevin you are right. I better correct a few spots that could be giving me grief. I still have the same kiln from Phil Teefy from 30 years ago. Wow eh! New lid though BUT I do know where I should add abit of fiber.  Les

Les

Give out Free Hugs!

website: http://www.twinvision.fusedglassartists.com

website: http://www.twinvision.fusedglassartists.com

-

twin vision glass

- Posts: 570

- Joined: Thu Apr 29, 2004 12:55 am

- Location: Invermere,B.C. Canada

- Contact:

Re: Quick technical question

Just when you think you have solved a power outage problem my haste did not help in reheating to 1100 F. AND well the piece DID thermal shock from tooooo quick a temp rise to 1100 F. Soooooooo now I have added MORE glass and will attempt again to refire. Not feeling optimistic BUT am taking 24 hours up to 1220 (my lucky number. Hmmm eh!) holding for 2 hours to get things warm and even. Then up to 1480 and the rest is the same as always. I will keep you posted. I covered all the fracture lines and hope it will look sort of O.K. Did not like the trees anyways.

Give out Free Hugs!

website: http://www.twinvision.fusedglassartists.com

website: http://www.twinvision.fusedglassartists.com

Re: Quick technical question

Les,

I am so sorry this piece is giving you fits. Your "magic" number is almost the same as mine when it comes to reheating difficult pieces. 50 degree ramp is maddening slow, but it works! Best of luck with this.

Sharol

I am so sorry this piece is giving you fits. Your "magic" number is almost the same as mine when it comes to reheating difficult pieces. 50 degree ramp is maddening slow, but it works! Best of luck with this.

Sharol

-

twin vision glass

- Posts: 570

- Joined: Thu Apr 29, 2004 12:55 am

- Location: Invermere,B.C. Canada

- Contact:

Re: Quick technical question

Well I am not optimistic but no harm done accept another jar of lovely 1401 5 pound frit. Thanks for the incouragement Sharol and Kevin has reminded me to make sure the kiln has NO leaks of air where the cold can come in. Les

Give out Free Hugs!

website: http://www.twinvision.fusedglassartists.com

website: http://www.twinvision.fusedglassartists.com

-

twin vision glass

- Posts: 570

- Joined: Thu Apr 29, 2004 12:55 am

- Location: Invermere,B.C. Canada

- Contact:

Re: Quick technical question

Give out Free Hugs!

website: http://www.twinvision.fusedglassartists.com

website: http://www.twinvision.fusedglassartists.com

Re: Quick technical question

Beautiful skies, Les

And good luck for your success in general, with this piece.

I'd love to see you make an abstract painting on glass using this method.

Would be great.

All the very best,

Havi

And good luck for your success in general, with this piece.

I'd love to see you make an abstract painting on glass using this method.

Would be great.

All the very best,

Havi

Haviva Z

- - - - with a smile

"Speed comes from the Devil" - (an Arabic proverb)

http://www.havivaz.com

- - - - with a smile

"Speed comes from the Devil" - (an Arabic proverb)

http://www.havivaz.com

-

twin vision glass

- Posts: 570

- Joined: Thu Apr 29, 2004 12:55 am

- Location: Invermere,B.C. Canada

- Contact:

Re: Quick technical question

Oh I love a challenge Havi, I will attempt and keep you posted. I have some great colour bar slices that I just spent a day sawing and love the reactions I got and want to use it with Opaline!!! Yum! Les

Give out Free Hugs!

website: http://www.twinvision.fusedglassartists.com

website: http://www.twinvision.fusedglassartists.com