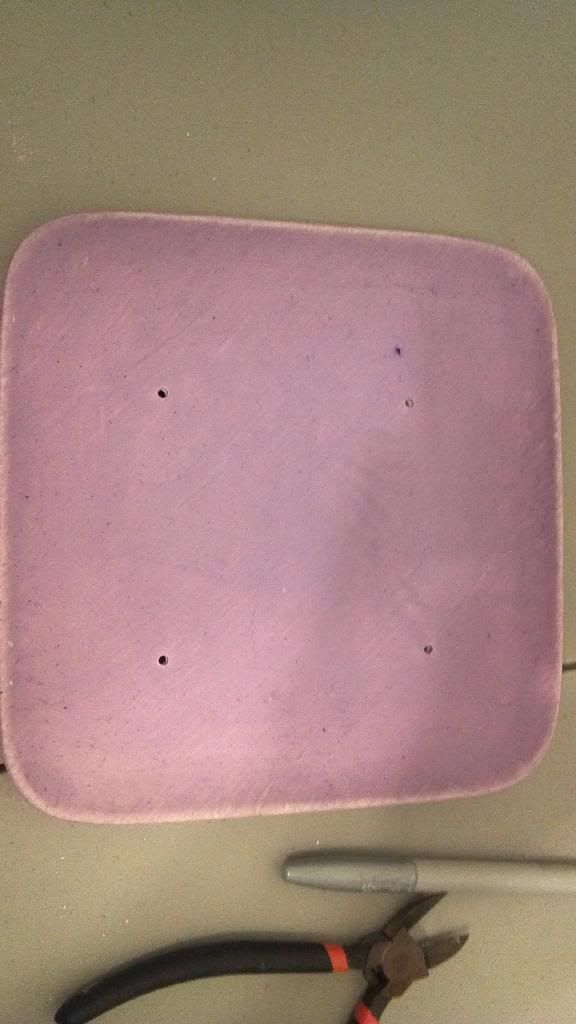

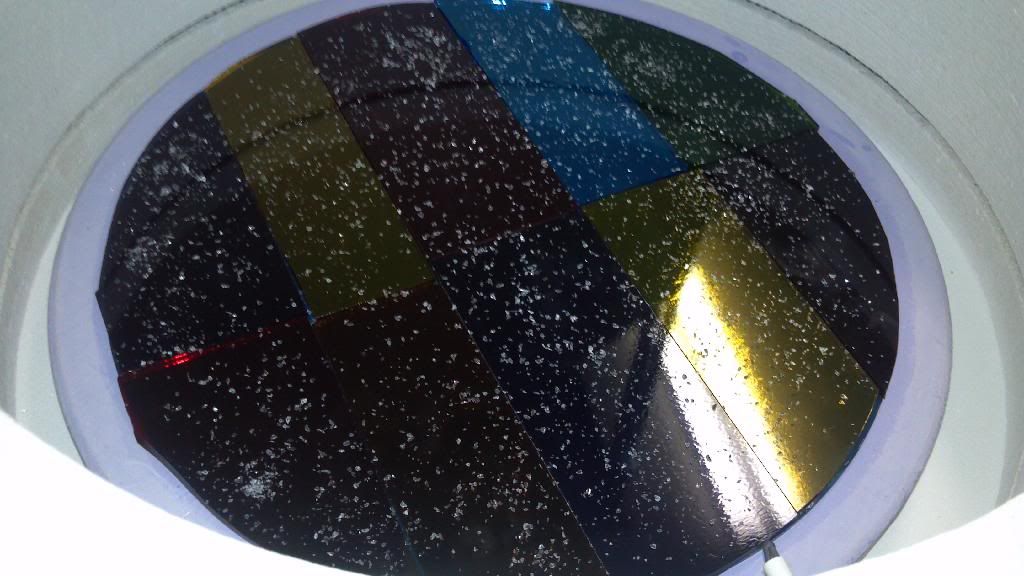

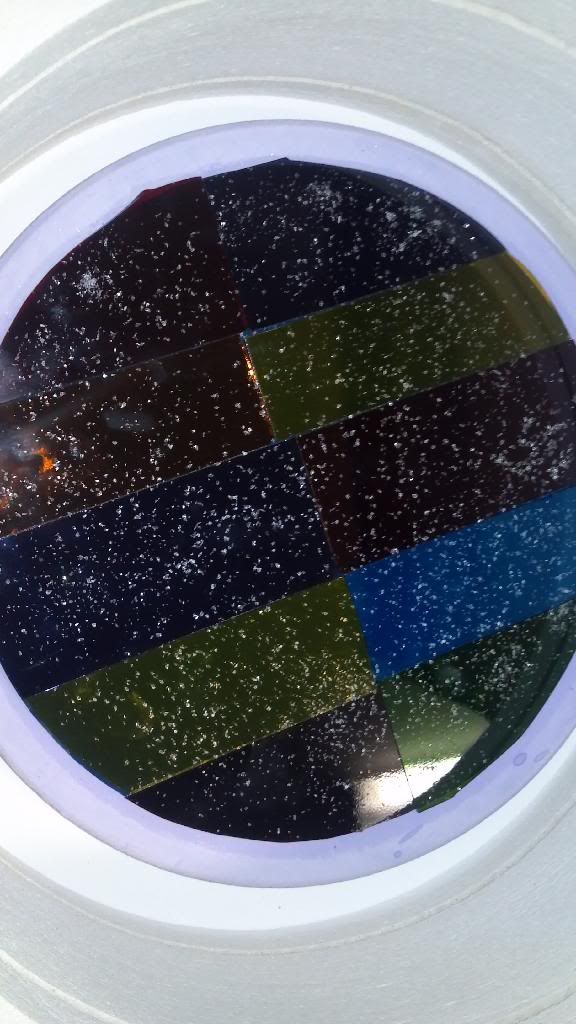

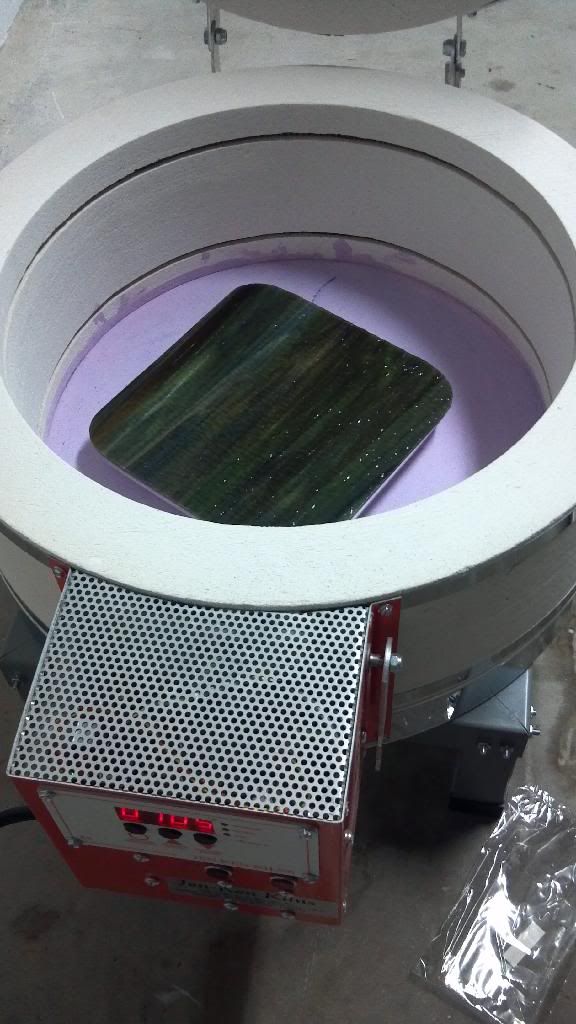

The North Carolina snowstorm delayed the shipment of glass, so for now, what you see is regular stained glass, COE of XYZ. Only single sheets firing, of course. Used the devit fluid by brushing it on and letting it dry. The real System 96 glass will be here Tuesday.

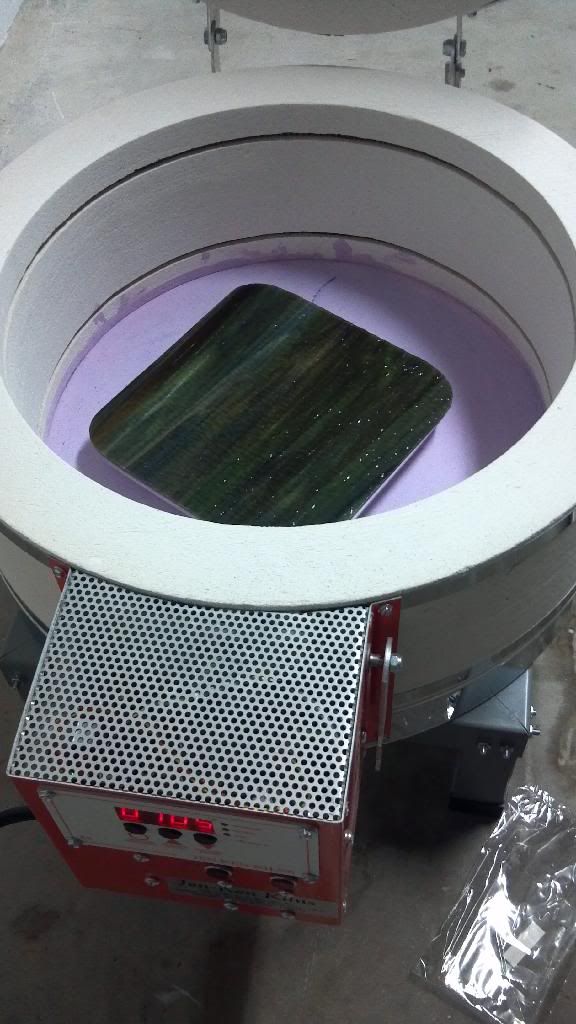

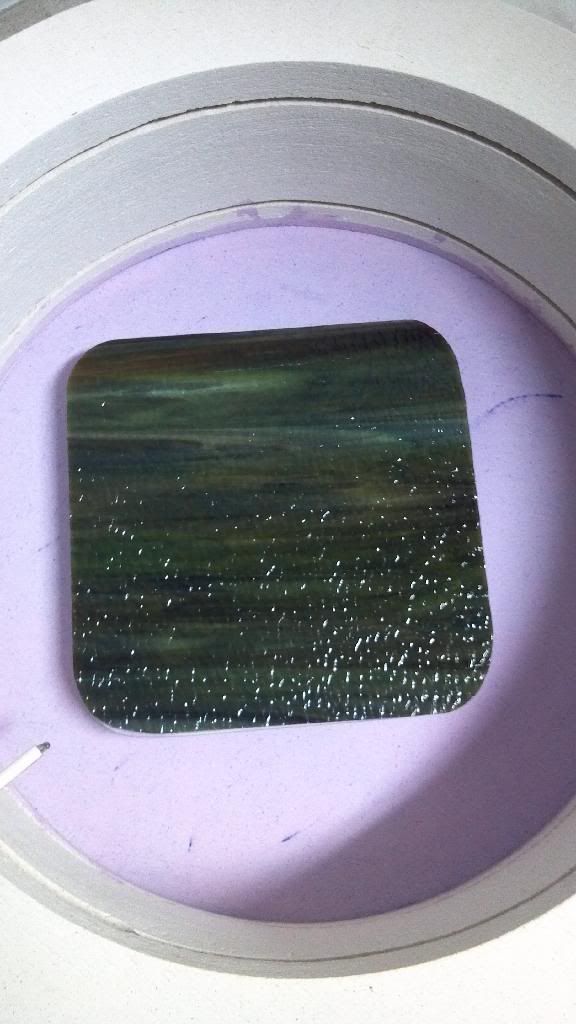

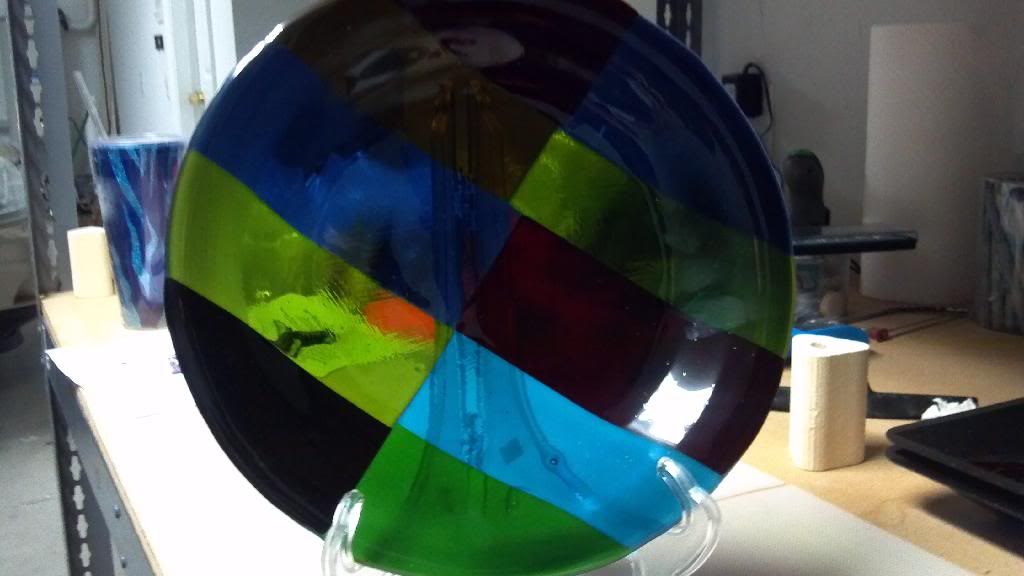

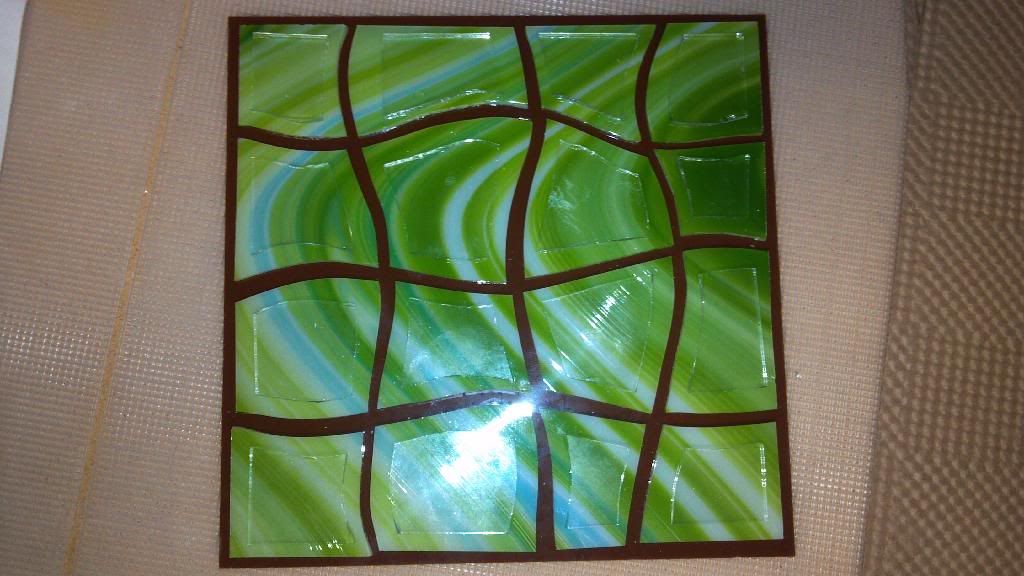

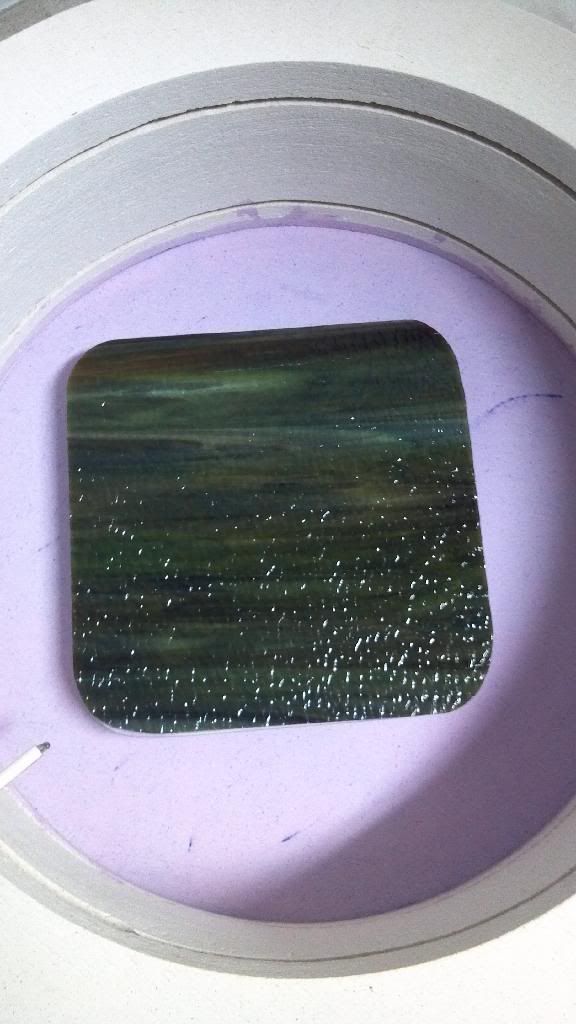

First square plate with textured glass came out great!

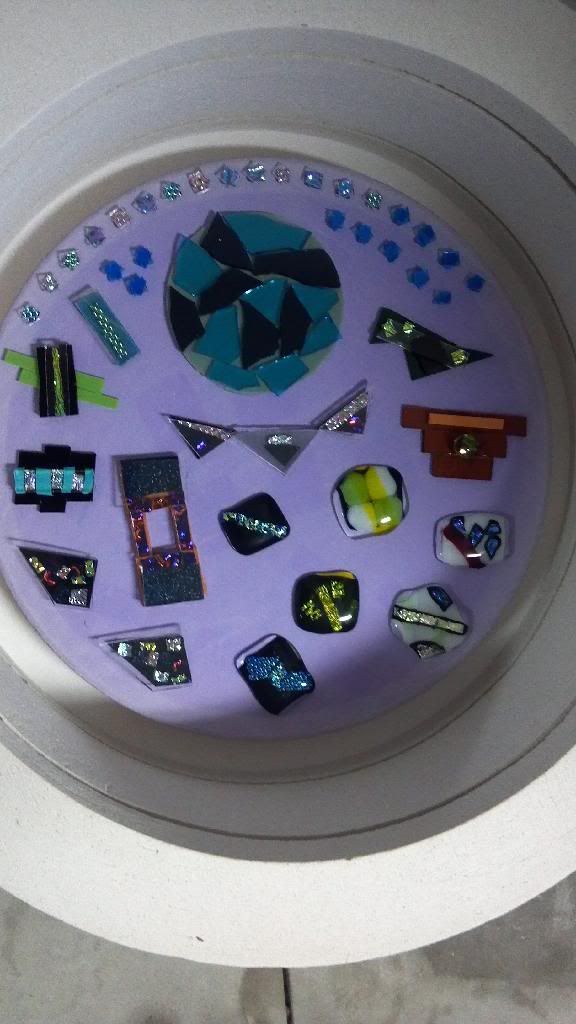

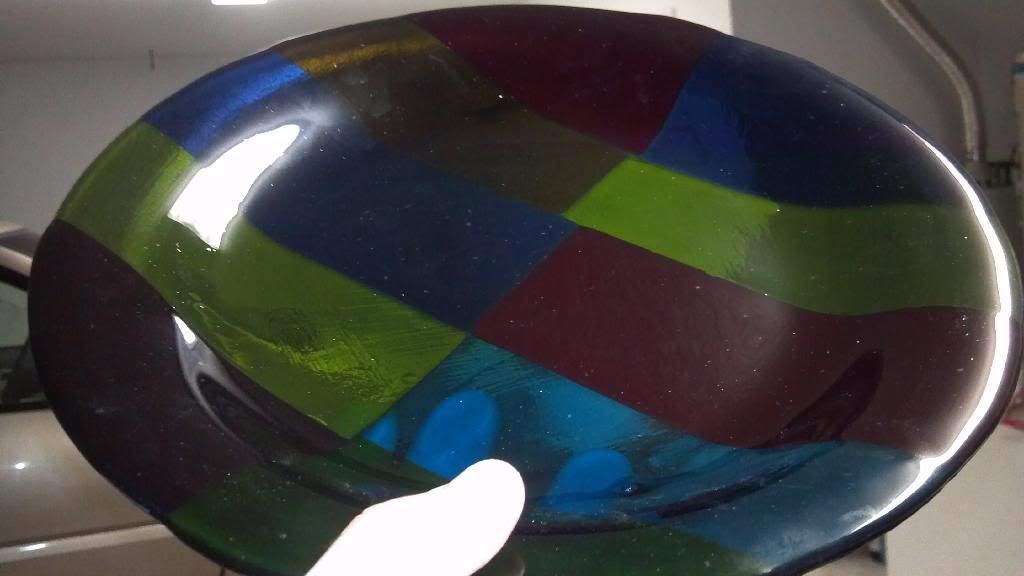

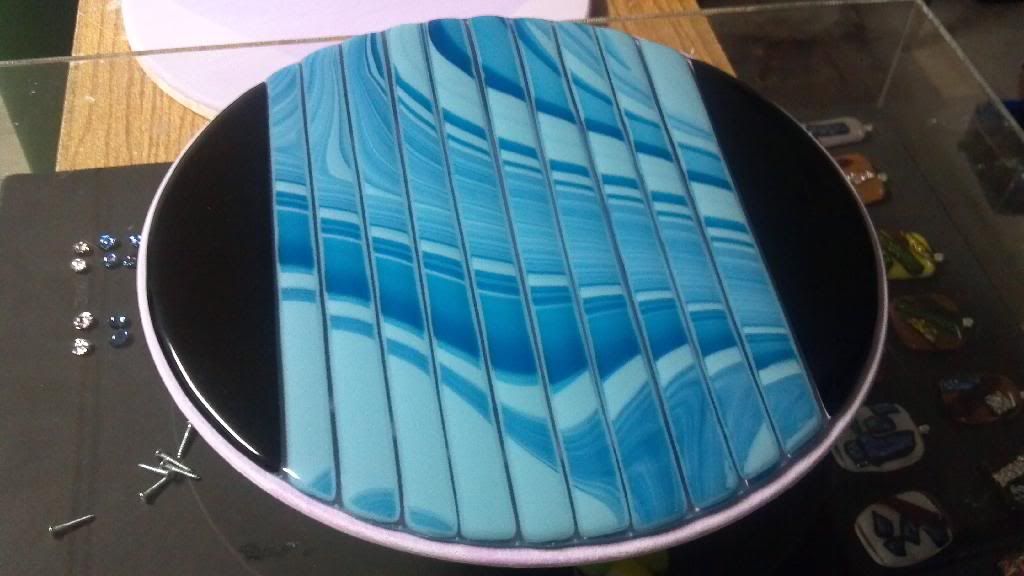

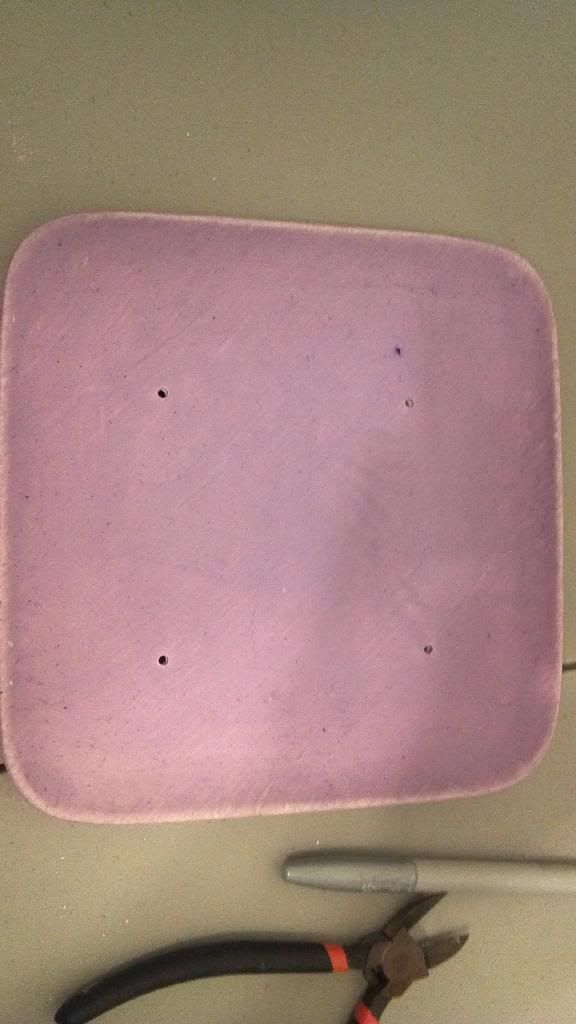

Second firing was a triangular bowl (blue) and an oval shaped dish. I didnt set it on kiln furniture, and the oval dish has a few bubbles on the bottom but is actually solid. My mistake. The blue dish slumped in one corner but not the other two. I thought I made the glass too big even though none overhung from it.

Third firing I made another plate, which cracked in half when cleaning it after pulling it from the kiln the following morning. Since it was really wispy glass, my guess it was just incompatible. And then another triangular bowl to see if I got the mold right, and what do you know, it wasnt.

So, that's what we've got so far. Any suggestions?

For the kiln, it was fired in "Small Piece Slumping" fire schedule built into the kiln by Jen-Ken as the manual said if the piece is less than 3/8" thick to use that schedule. Leave it to the first piece to come out great and the rest wonky.

And thanks to everyone for their participation and help so far! We *really* appreciate it!!

Ben & Vanessa