| |

#40 Paul Tarlow

|

| |

|

| |

#41 Anitra Watley Allen

Now

that all my glass emissaries have been labeled, bagged, boxed and shipped

all the things that I would have, could have and should have done to

make them better come to mind. They will be strewn all over the country,

well the world for that matter, conjure them perfect I would; but the

deadline for their transport had arrived, and I have no more time to

give them. So I send my ambassadors off into this world Now

that all my glass emissaries have been labeled, bagged, boxed and shipped

all the things that I would have, could have and should have done to

make them better come to mind. They will be strewn all over the country,

well the world for that matter, conjure them perfect I would; but the

deadline for their transport had arrived, and I have no more time to

give them. So I send my ambassadors off into this world

with as much finishing as I could give them at this instant. I pray

that they’ll make me the proud if I ever meet them again. There

is much I would have done differently to save time and some things wouldn’t

have done it all. A superior learning curve was obtained during this

endeavor. For instance:

• There is a vast gradient of temperatures in my kiln from top

to bottom

• Skills to reduce and combat devitrification were acquired

• Discovery of the fact that I must be crazy was encountered more

than once

• Small matter how careful one is in cutting glass one will still

bleed on it

• Inclusions find air bubbles irresistible

• Not all copper wire is created equally

• Glass is a lot like hard candy

• In the same way that first cousins really should not marry, clay

artists should stay away from glass photo

• There’s always a piece of expensive equipment one could

use to do the job easier if not better and faster

• The more you learn the more there is to learn

• CMC leaves a residue

• One can not over clean glass

• Prototypes are easier than production

So therefore my time was not wasted.

Introduction: Introduction:

Glass log: Jan. 6, 2006 I've taken on a rather large and unprofitable

glass project. I am exchanging “mag-glass/Magless” (refrigerator

magnets without magnets, made of glass) with 125 other glass artists

from around country (and a few from the world at-large). The deadline

is February 14 (actually to 17th, but it needs to be delivered by then);

that seems so far

away in November when I signed up; but now it's just next month. Yesterday

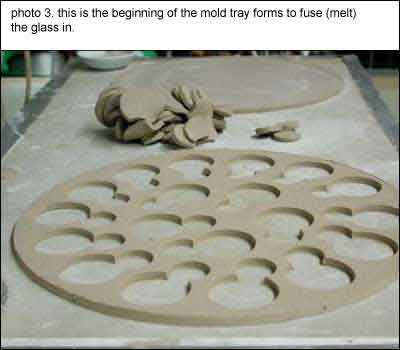

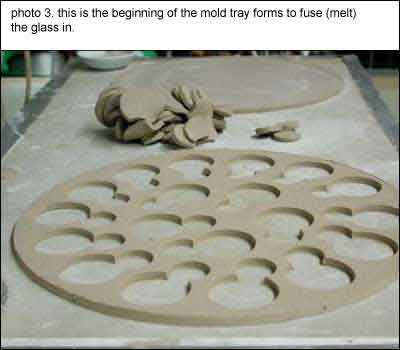

the second stage of this project was completed; and that was making

the clay molds in

which to form the “mag-glass”.

It takes 2 or 3 days to dry before the trays is ready for the bisque

firing. Bisque firing at 1800° Fahrenheit, cone 06, is run after

the clay is completely dry. The clay mold trays take 2 or 3 days to

totally dry ready for bisque firing at 1800° Fahrenheit, (cone 06).

Surprisingly enough, I am not in full panic mode yet but I am starting

to be concerned about the

time left.

Glass

log: Jan.07, 2006 Glass

log: Jan.07, 2006

“What is the point of this magnet business?” a fellow clay

artist asked me. Well I should obtain 125 glass pieces in this exchange.

Well as lease in presumption. It seems at lease five people never get

it done. I should recieve some one hundred plus maglesses. Let me send

you to last year’s exchange,

http://www.warmglass.org/magnet/2005_Section_One.htm. You will notice

some of these are made with pride and great expertise while others are

done on a wish and a prayer. Various ones have well equipped glass shops

while others who get by with the bare necessities. The last few years

have yielded a charming assortment of glass pieces. I desire to have

a collection of glass boggles like this. This could be a grand teaching

tool. “Ahhhhhh,”says my friend, knowingly. “There is

no money in it” Why then am I doing this, one might as? Well…

to tell the truth, I’m not sure. I am not certain why I am playing

with glass to begin with; after all, I am a clay artist. I will have

this to show for the winter of 2006, maybe? Yes, I’m having fun

with it but it is costing me time and resources without justification;

it is sort of like a vacation. I’d been keeping the time I’m

wasting here a secret from my spouse. Yes it is a wayward little magless

secret. The four trays I made for my glass are drying now and I will

bisque today or Monday. 4 trays of 16 cavities each means I’ll

have 64 pieces in the first full fuse firing. I could not help myself

on the last two trays I carved grooves into the bulb bottoms; I’m

sorry now for all other the magless won’t be exactly the same.

I’d plan on making extras in case of breakage and seconds. It is

very hard for me to produce the same design without change. I have the

same problem making cookies.

Glass

log: January 10, 2006. Glass

log: January 10, 2006.

The bisque firing for tray molds ran yesterday; the iln is cooling;

it is around 500° now. This afternoon, the kiln can be unloaded

and six or seven layers of kiln primer will need to be painted on to

these forms. There's plenty to do during the wait because now 150 of

those wire dolls need to be made. Certainly they won't all be made before

the kiln cools. The wrapping of these dolls has become much quicker

now that a couple of dozen have been made. The prototype took a nice

bit of time, but once the sequence of wrapping was figured out they

can be done mindlessly while watching television. I however will sit

on the patio and enjoy watching the quail, the bunnies and the neighbor’s

horses once the sun burns the chill off this morning’s air. The

wire used for the dolls was obtained from an electronic salvage supplier.

It is copper wire even though it appears silvery, most likely it has

a tinned coat, probably lead. After embedding in glass, it turns a reddish

copper color. After wrapping these little figures, I flattened them

on an anvil with a hammer; the flattened wire doll embeds easier between

glass layers. I get quite a little rhythm section going as I flattened

my wire dolls, which scares most of the critters away, all but the flies

that is.

Glass

log: 1/17/06 Glass

log: 1/17/06

After a week of preparation and cutting glass the first batch of glass

for my magnet/magglass were fired to cone 014. They are truly awful;

they look more like tubes than bulbs, very misshapen. They have many

unsightly bumps and bulges and points; in short they are deformed. I

also noticed some devitrification. Oh well, I'll rework them; I can't

have them looking that crude. I must have taken the kiln up too slowly.

Perhaps I should mention that I’m using Bullseye glass CEO 90.

The kiln is a small Paragon, ceramic kiln; it has nearly one cubic foot

capacity. It's a manual kiln, just a sitter and a timer; there's neither

computer interface, nor fire mate. I turn the kiln from low to medium

to high at single hour intervals. It has no elements on either the floor

or the lid, only in the walls. The trays are stacked with 1 inch between

levels. After firing the color of the copper wire varies from white

to copper to black; whatever was used to tin coat that wire is giving

some odd results, there is a remote possibility that it is a metal other

than copper. Glass log: 1/18/06 First thing this morning after grooming

was for me to go out to the studio and flip the switch on the kiln.

That's right, lot 2 is firing as I write this. It will probably take

four hours to come to temperature; that's about 1500° Fahrenheit.

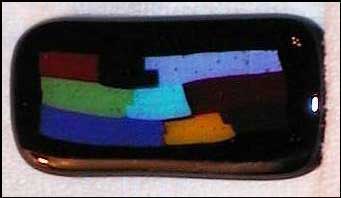

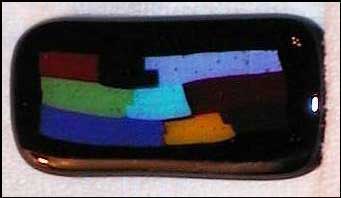

I'll let it soak this photo 8. Very disappointing this first batch,

I'll washed and fire them on their reverse side. photo 6 before (left)

and after.

After

firing the color of the copper wire varies from white to copper to black;

whatever was used to tin coat that wire is giving some odd results,

there is a remote possibility that it is a metal other than copper. After

firing the color of the copper wire varies from white to copper to black;

whatever was used to tin coat that wire is giving some odd results,

there is a remote possibility that it is a metal other than copper.

Glass log: 1/18/06

First thing this morning after grooming was for me to go out to the

studio and flip the switch on the kiln. That's right, lot 2 is firing

as I write this. It will probably take four hours to come to temperature;

that's about 1500° Fahrenheit. I'll let it soak this time at temperature

for about 10 minutes before a crash cooling it to 1000°F. I've read,

in theory, if I let it sit at temperature it should level out nicely.

Glass must be cooled, very slowly from 1000° back to room temperature;

the hardest thing for me to do is wait the 24 hours it takes to cool.

I learned this the hard way. Once I opened a kiln early; that mistake

caused cracks. Now I trust a Pyrometer.

Results of firing:

The copper wire from my old battery cable has a blue/green halo around

it, possibly from battery acid. Few figures were made from this wire,

but it's an interesting side effect that I may try more of. The figures

that I dipped in the ceramic pigment have an attractive patina. The

iridescent glass highlights embedded between layers is hardly noticeable

unless you're looking for it.

Glass

log: January 22, 2006 Glass

log: January 22, 2006

Unloading today’s kiln, which was fired at cone 015 I’ve found

borax solution also works well on the devitrification, but one must

be very careful in its application. If any of the solution drips onto

the reverse side of the glass there is a problem with kiln wash sticking

to one’s work, ensuing in the need to rock tumble it. It is best

to spray on the borax solution, but of course that takes another piece

of equipment; that is a sprayer plus the compressor to run it. Also

I’ve read sandblasting the surface and firing will solve all devitrification

problems providing of course, that one has a sand blaster. The floor

of the kiln is much colder than the rest the kiln. Therefore, the bottom

inch or so of the kiln is not suited for full fuse. The top of the kiln

near the lid is also too cool for a full fuse.

Glass log: 2/07/06

Busy, busy, busy and yet, so far from being done. Here I am coming close

to that February 14 deadline and I'm only one third of the way there.

My magless secret is out of the bag as the hubby took vacation days

this week; he notice my attentions were elsewhere. “Honey”

I said, “I’ve got a deadline.” He is disenchanted now,

but just wait until I dazzled him with the most intriguing refrigerator

magnets collection in all of Arizona!

The glass pieces were developing a cloudy haze from being fired multiple

times. The scummy haze is called devitrification; I understand it is

a growth of microscopic crystals on the surface of the glass; it's the

mark of a true amateur, which I just happen to be. To counteract the

spots of scummy surface I've purchased a rock tumbler and tumble the

glass pieces, overnight. After tumbling, the result is an evenly frosted

surface.

Luckily

the rock tumbler was on sale, only 20 bucks! An artist friend loaned

me her tumbler, which hadn't been used for 20 years; but it had all

the carbide grits with it. The loan tumbler was a much better make than

the Chinese one that I bought. Between the two tumblers I was able to

get 50 of them ground off and fire polished. They're bit of all right!

My Chinese rock tumbler has busted to drive belts, and is now out of

commission while the 20- year-old American-made one is still going strong. Luckily

the rock tumbler was on sale, only 20 bucks! An artist friend loaned

me her tumbler, which hadn't been used for 20 years; but it had all

the carbide grits with it. The loan tumbler was a much better make than

the Chinese one that I bought. Between the two tumblers I was able to

get 50 of them ground off and fire polished. They're bit of all right!

My Chinese rock tumbler has busted to drive belts, and is now out of

commission while the 20- year-old American-made one is still going strong.

Conclusions:

On the whole this was a most expensive, laborious, time-consuming project;

Speaking of time, it took the entire day just to put them into little

plastic bags with labels on them. It is factual “that every good

idea is 1% inspiration 99% perspiration”. It helps to know that

there are at least 125

other people in this as foolish as I am.

If I were to do it again, I’d probably use float glass and metal

oxides rather than that costly Bullseye art glass. I’d also want

a partner, preferably one with greater expertise; and a better-equipped

studio plus a shoulder to cry on. However, I feel now that I shall not

do this again.

A helpful discovery I shall pass on is that latex exam gloves can reduce

the amount of glass sliver cuts on one’s hands as well as keeping

one’s hands warm in a chilly studio.The last pieces out lost the

angst those first worked and reworked ones had. As a process became

a little more streamlined the work became more relaxed and refined.

Cone 014 seem to be the best firing temperature for full fuse in the

belly of my ceramic kiln; that is 1525 degrees F or 830 C. This temperature

allows me to fire polish on the floor of the kiln

and to hard tack fire at the top of the kiln. It does little to crash

vent the kiln to stop devitrification. It may even be hard on the kiln

and the furniture. When using cones soaking after the cone bends does

minuscule to shape. The soft diffused surface of the rock tumbled glass

was preferred but I had to stay the course of harder fire polished look.

Thanks be to God, that I was healthy enough, wealthy enough and spiritually

inclined to finish this project. Now that it’s all over I can shout

out loud, Glory, Glory Hallelujah!

|

| |

|

| |

#42 Kent Allen

What

I learned: What

I learned:

Perfecting the Magless will take more time than originally estimated.

Punching out over 252 butterflies is a tedious task.

I originally started the project trying to fuse a penny between a layer

solid background color and a clear layer. I quickly learned that not

all pennies are created equal. Here's a Penny's History

• The composition was pure copper from 1793 to 1837

• From 1857, the cent was 88 percent copper and 12 percent nickel,

giving the coin a whitish appearance.

• The cent was again bronze (95 percent copper, and five percent

tin and zinc) from 1864 to 1962.

(Note: In 1943, the coin's composition was changed to zinc-coated steel.

This change was only for the year 1943 and was due to the critical use

of copper for the war effort. However, a limited number of copper pennies

were minted that year.

• In 1962, the cent's tin content, which was quite small, was removed.

That made the metal composition of the cent 95 percent copper and 5

percent zinc.

• The alloy remained 95 percent copper and 5 percent zinc until

1982, when the composition was changed to 97.5 percent zinc and 2.5

percent copper (copper-plated zinc). Cents of both compositions appeared

in that year.

I found that new pennies melt into what is best described as small

zinc BB’s. I then tried 1962 to 1981 vintage, the pennies didn’t

melt, but got a lot of bubbles. I tried, 2 months every weekend 2 firings

every Saturday and Sunday, to eliminate the bubbles with different soak,

ramp times, temperatures, glass etc. No matter how slow the ramp down

and soak temperatures of the penny fusing schedule, all of the pennies

would crack the base layer. I could never eliminate the

bubbles completely.

Time and patience running thin, I switched over to pure copper butterflies,

no bubbles. For this set of Magless, I used Spectrum System 96 Hi-Fire

Iridescent Black #I/1009SF as the background and Spectrum System 96

Clear Smooth Cathedral #100SFS as the clear cap.

Fusing Schedule:

| Rate (°F/Minute) |

Temp (°F) |

Hold Time |

| 300 |

250 |

25 min |

| 300 |

750 |

25 min |

| 60 |

1220 |

30 min |

| 60 |

1300 |

15 min |

| 600 |

1480 |

15 min |

| AFAP |

1000 |

10 min |

| 90 |

970 |

2 hrs |

| 1200 |

750 |

1 min |

|

| |

|

| |

#44 Barbara Elmore

Ok,

from the beginning, I took a class with Brad Walker a few months ago,

and one of the things I brought for an experiment was some brass steel

woolish stuff. Made by Mr. Clean, If you are careful, you can punch

out one end, and un-crochet it. If you roll it out, it looks like chain-maille

(not sure if that is the word, think of jousting in Medieval times and

the stuff that covered their arms). Ok,

from the beginning, I took a class with Brad Walker a few months ago,

and one of the things I brought for an experiment was some brass steel

woolish stuff. Made by Mr. Clean, If you are careful, you can punch

out one end, and un-crochet it. If you roll it out, it looks like chain-maille

(not sure if that is the word, think of jousting in Medieval times and

the stuff that covered their arms).

Wrapped the brass around a Bullseye clear iridized glass in a cross

hatch pattern, with plain Bullseye glass on the top and the bottom.

Did this in a pattern bar size, 6 x 10 or so, and ramped up very slowly,

did a bubble squeeze and held at 1450 for 30 minutes.

Everything looked OK.

Then I cranked up the Taurus #3 and the blade went flying. No words

of wisdom from Gemini. So, we took off and went to Harbor Freight (about

80 miles away) and bought a wet tile saw, that was luckilly on sale,

for $59.00 or so.

Sliced up the pattern bars into a 1 x 1 1/2 rectangles, hand polished

the edges with three different diamond pads, put a Borax overspray on

them and pretty much

followed the same temps and time, but at a lower top temperature, 1350,

so I wouldn't round out the sides, and keep it rather crisp, with less

of a hold.

Wrong.

The wrapped middle layer of iridized clear glass, covered with the

copper wire, albeight very, very, small gauge, wouldn't let the whole

thing completely fuse. The edges were, well, yucky. 40% went into the

trash, 60% are included, but with

apologies

What I have learned? 3 layers of glass is too much without thinking

ahead to how the glass will behave (or absolutely NOT behave) when it

isn't damed.. Looks like a tire with bubbles, everywhere they could

form.

Places (like big, big zits) in the top of the cab popped off and landed

on the other side of the kiln. Cabs moved, and moved a LOT, to meet

with other cabs even tho I had spaced them well and they were not wet,

nor was anything else in the kiln.

Did the best that I could, and tried to figure out what to do next.

Today is Tuesday, the rest are drying, and I'll be lucky if they make

it to Texas by Friday.

This second phase has been made individually, as was the prototype.

The sandwich is made up of graduated pieces of glass. The bottom layer

is approximately 2 and 3/4 inches. The middle is made up of a slightly

smaller piece, of maybe 2 1/2 inches of iridized glass wrapped in copper,

and the top is the largest piece ( 2 13/16" or a bit more) so that

it can cover and drape down over (hopefully) the rough edges of the

copper in the middle.

Final schedule: for a square 3 layers thick ,and 2 and 13/16 or a bit

more at its widest.

1. 300 dph to 1000, hold 10 minutes

2. 200 dph to 1250, hold 15 minutes

3. 400 dph to 1475, hold 30 minutes

4. 500 dph to 960, hold 35 minutes

5. 250 dph to 700, hold 10 minutes.

6. Off, and let cool to room temperature overnight.

I have tweaked and tweaked this schedule and still don't understand

where the things are blowing up and moving all over the kiln!

I really wanted more of the blue color from the copper, but mostly

got red and purple. In some cases, where I was doing the pattern bar

thing, the colors were all over the place, blues on the outside (that

kind of "leaked" into the clear glass),

then the purples and reds and golds as you got to the center. Maybe

I didn't hold long enough on the way up?

The colors of the copper have been mystifying......................Some

stayed a copperish purple, some a copperish gold, and some turned a

beautiful blue/green.

Funny thing, tho, all these colors were sometimes in the same pattern

bar, with holds to even the temp, and holds to minimize the bubbles.

Go figure. The one I did in Brad Walker's class was great. The top layer

was cut larger so that it could come down and cover the sides to hide

the mesh, colors were great, no problem.

I guess it's one of those things that needs to be done individually,

and I will finish this up tomorrow or when I can open the kiln.

|

| |

|

| |

#45 Cecilia Davis-Taylor

|

| |

|

| |

#46 Robert Krug

|

| |

|

| |

#48 Tim Smith

|

| |

|

| |

#49 Kelly Alge

|

| |

|

| |

#50 Linda Hattershide

|

| |

|

| |

#51 Tony Smith

|

| |

|

| |

#52 David Wingo

|

| |

|

| |

#53 Darlene Palmer

How-to

for "Dichroic Flats" How-to

for "Dichroic Flats"

Rectangular BE black base, a slightly smaller piece of Wasser metallic

antique copper, and a small piece of dichroic balloon glass. All pieces

glued together. A drop of turquoise Glassline paint is added to each

corner. Then after allowing the glue to dry overnight, each piece is

turned upside down on the kiln shelf and fused at 500 degrees to 960,

then fast as possible to 1450. No hold. Open door to fast cool to 1050,

then left overnight.

What I Learned....

The idea was to make the dichroic side of the magless as flat as possible

and have the Glassline paint dots in the corners end up on the sides.

In order to have each piece of glass be centered, they needed to be

glued and left to dry overnight. The first couple of test pieces didn’t

have enough glue and fell apart when turned over. Learning my lesson,

I added more glue and left overnight again. This time they remained

together and fired correctly.

|

| |

|

| |

#54 Marsha Toms

My

maglesses are miniature pot melts done in very tiny clay pots. The glass

I used was about ¾ clear mixed with yellow, adventurine green,

and cobalt (I think) blue. I enlarged the holes on the pots and stacked

the glass inside horizontally. Fired to 1700 degrees for 30 minutes.

I was able to fire about 10 at a time and I was able to keep reusing

the pots. I hope you enjoy My

maglesses are miniature pot melts done in very tiny clay pots. The glass

I used was about ¾ clear mixed with yellow, adventurine green,

and cobalt (I think) blue. I enlarged the holes on the pots and stacked

the glass inside horizontally. Fired to 1700 degrees for 30 minutes.

I was able to fire about 10 at a time and I was able to keep reusing

the pots. I hope you enjoy

|

| |

|

| |

#55 Michelle Gotthold

My

magless is a 1.5" square of bullseye opal (many are curious colors)

topped by a 1" square of white. The white square was sprinkled

with Thompson enamels then covered with clear frit. All was brought

to a full fuse. What really surprised me was how much difference there

was in how the different colored bases "beaded up" -- I know

different colors absorb heat differently, but I was surprised by just

how much! The steel blue pieces fused so much they were almost more

round than square while the red and powder blue pieces were closer to

tack fused than full. (I re-fused the tack fused pieces so they would

flatten out more.) I also learned that I can only do one full fuse with

opals on a shelf before changing the kiln wash -- one whole batch came

out with needling and rough edges when I tried to get a second firing

on one shelf. My

magless is a 1.5" square of bullseye opal (many are curious colors)

topped by a 1" square of white. The white square was sprinkled

with Thompson enamels then covered with clear frit. All was brought

to a full fuse. What really surprised me was how much difference there

was in how the different colored bases "beaded up" -- I know

different colors absorb heat differently, but I was surprised by just

how much! The steel blue pieces fused so much they were almost more

round than square while the red and powder blue pieces were closer to

tack fused than full. (I re-fused the tack fused pieces so they would

flatten out more.) I also learned that I can only do one full fuse with

opals on a shelf before changing the kiln wash -- one whole batch came

out with needling and rough edges when I tried to get a second firing

on one shelf.

|

| |

|

| |

#56 Linda Hassur

I

started trying to cut out strips that were straight enough to fuse together.

I soon realized this was going to be a big job. I had a "Silberschnitt

Roll up pad with parallel cutter" that I hadn't used but a couple

times. I got it out and that was the answer. You can cut straight thin

strips that are very accurate. I cut out strips of all colors of opaque

90COE BE glass. I used BE opaque white for the I

started trying to cut out strips that were straight enough to fuse together.

I soon realized this was going to be a big job. I had a "Silberschnitt

Roll up pad with parallel cutter" that I hadn't used but a couple

times. I got it out and that was the answer. You can cut straight thin

strips that are very accurate. I cut out strips of all colors of opaque

90COE BE glass. I used BE opaque white for the

bottom piece and placed the colored strips on top of it. My kiln will

only hold a 10X12 inch piece of glass so that was the size I fired.

Unfortunately, my kiln started "spitting" small pieces of

kiln brick from the top elements. So it ended up taking a lot more time

since I had to drill these pieces out and refire. I also had problems

with devit on some of the colors so used overglaze for that problem.

I cut the large piece of glass into strips about the length of each

heart. I used a pattern that I traced onto these strips. I used a Pilot

thinline pen for this purpose. I roughed out the shapes using a glass

cutter and breaking pliers. I then applied Chapstick on the pen lines

so I could keep the pattern visible during the grinding process. On

pieces that were too much to grind, I used a glass saw to get

the shape more accurate. I then did a lot of grinding. I used a small

grinding head to shape out the tops of the hearts. They were then fired

again and sometimes again and again because of devit. I just kept using

either Spray A or clear overglaze on the hearts and fired again.

I was pleased with the way they turned out. To me they resemble striped

hard candy.

|

| |

|

| |

#57 Katy Wills

Little

Keyboards Little

Keyboards

Cut base pieces and add stringer to be the spaces between fuse (1380).

Add the keys and fuse again (1330).

Next time, I would fuse the bases upside down so that the doesn't move.

I lost a few pieces firing the way I did.

|

| |

|

| |

#58 Patti Rohwer-Nutter

Mine

were pretty simple - I was initially inspired by African Kiffa beads.

In Northwest Africa, women grind bottles to make powder, make a paste

with gum arabic and/or spit, and then make beads decorated with intricate

patterns of powdered glass. The beads are then fused on sand in a can

on top of a charcoal fire. (See http://www.lapidaryjournal.com/feature/june00str.cfm). Mine

were pretty simple - I was initially inspired by African Kiffa beads.

In Northwest Africa, women grind bottles to make powder, make a paste

with gum arabic and/or spit, and then make beads decorated with intricate

patterns of powdered glass. The beads are then fused on sand in a can

on top of a charcoal fire. (See http://www.lapidaryjournal.com/feature/june00str.cfm).

I used Bullseye powder mixed with distilled water and different amounts

of gum arabic, Klyr-Fire and/or clear mucilage (just what I happed to

have on hand). All three binders worked equally well, but black powder

mixed with mucilage makes a

thick goo that feels like a mixture of silly putty and snot!

Shaped "biscuits" out of a stiff powder mix, let dry for

an hour or so. Drizzed or dotted different slurries of powder, dried

under a hot lamp for 8-12 hours, then fused (either 1400 x 10' or 1420

x 20'). Vented the kiln on the way up until it reached 1000-1100 degrees

to burn off all glue residue.

At first I tried to make patterns reminiscent of those found on kiffa

beads, but it was very laborious getting the suspended powder evenly

suspended and keeping consistent lines and dots. I started randomly

drizzling the powder slurry and aiming for a marbled look. I'm planning

on making my own CMC "liquid stringer" mix the next time I

try this, which will hopefully give me better control.

|

| |

|

| |

#59 Denise Dennstedt

I

decided to combine two techniques with my mags. Copper inclusions &

powdered frit stenciling. My magless’s consists of 2 layers of

Bullseye 90 COE glass. The base glass is white & the top glass is

clear. I was going for a look of depth with the moose behind the tree. I

decided to combine two techniques with my mags. Copper inclusions &

powdered frit stenciling. My magless’s consists of 2 layers of

Bullseye 90 COE glass. The base glass is white & the top glass is

clear. I was going for a look of depth with the moose behind the tree.

I tried two different coppers, one being a semi- thin sheet cooper

the other is an adhesive backed copper foil in sheet form. I used a

paper punch to cut out the moose shapes. I found that the preferred

the adhesive backed foil for three

reasons 1) it was thinner so, easier to punch, 2) it stuck to the glass

& stayed in place and 3, because it didn’t require a bubble

squeeze firing as did the other copper sheet.

I tried several different green frits before I settled on Adventurine

green. Each tree has two layers of powder.

The lay-up:

white/moose/clear/stenciled tree

firing schedule:

500/1400 -hold 10/full/960- hold 15/off (fire schedule for adhesive

backed foil)

500/1100-hold 20/150/1250 hold 5/600/1400-hold 10/full/960-hold 15/off

(fire schedule for sheet copper)

Next I added a 2nd layer of powder and took it up to not quite a full

fuse, I wanted a raised look.

500/1350-hold10/full/960- hold 15/off

And there you have it a moose in the woods

|

| |

|

| |

#60 Monika Libor

First

I would like to thank Brad for providing the Warmglass board and the

Warm Tips Section, which gives me the opportunity to learn everyday

about glass without having to travel and take classes. First

I would like to thank Brad for providing the Warmglass board and the

Warm Tips Section, which gives me the opportunity to learn everyday

about glass without having to travel and take classes.

This is the first time that I was able to take part in the Magless-Exchange,

and almost dropped out because the kiln-gods were not with me on two

runs (speak 100+ pieces), having trouble to get the material I needed

in my area, not enough time off from work etc

Thanks to Suzanne for her encouragement and setting my head straight

and getting me back on track again.

Loving chocolate (especially Belgian Chocolate) and having the insert

of one of those chocolate boxes to use as my master mold, just to try

it out, was the first step. Reading about pate de verre and color the

verre and curious to try it out to see were I can go with it was part

two. And thinking of my Grandma, my parents and all those delicious

fondant sugar sweets during Christmas time and on our Christmas tree

(oh sweet childhood) was part three.

Ingredients:

a. distilled water, plaster of Paris, silica flour (325 mesh)

b. Mold, Pam Spray, Cling Film, Tupperware or cardboard box

c. Glass, Frit, Powder, CMC, Mica, Airbrush, Hairspray

d. Hammer and news paper (to make Frit)

e. following Brads Book and casting guidelines (Warm Tips) and all the

other contributions on the Warmglass board about kiln casting,

f. Time, patients and a supportive spouse.

How to:

1. prepared mold, Clingfilm in cardboard box, master mold sprayed with

Pam,

2. mixing equal parts of distilled water, plaster and silica

3. pouring mold and releasing after it’s set and letting air dry

for 24hrs

4. using airbrush to apply mica on mold

5. filling molds with frit and powder in different layers and as high

as

possible

6. firing and cooling back to room temp (26 hrs)

7. checking, refilling and re firing,

8. Waiting, cleaning; and wishing for cold working equipment.

Firing Schedule (in my kiln Skutt GM1014): (wet mold)

I.) 200°- 225° hold 120min,

II.) 200°- 350° hold 120min,

III.) 200°- 850° hold 60min

IV.) 300°- 1050° hold 20min,

V.) 400° - 1375°hold 90min,

VI) 9999 to 950 hold 120min

VII.) 50 to 800 hold 30min,

VIII.) 50 to 700 hold 30min,

IX.)Let cool to room temp 12hrs+).

Reload and re-fire a lot faster since mold doesn’t have to dry,

but handle with care. Checking, cleaning, sorting and starting all over

again a few times.

What did I learn?

- have more material than needed; but I had fun smashing the glass to

make frit,

- start early if you have a day job, (more time to get more stuff)

- don’t loose patience and start over if the kiln gods fail me

again

- trusting my family if they tell me it looks “cool”

- And that take out isn’t that bad at all (if you don’t have

time to cook).

- Start saving to buy cold working equipment!

Monika # 60

*Be the Change you want to see in the World. (Mahatma Gandhi)*

|

| |

|

| |

#61 Larry Lunsford

|

| |

|

| |

#62 Dianne Van de Carr

I

made a new sheet of glass by fusing a base Bullseye 3304. I think it

was curious. The tiny pieces of dichroic were added across the surface

with tweezers, some face up and some face down. Then strips of 1441-50

were placed on top. It was fused to about 1440 with a 22 minute hold.

After the first fusing, I cut strips and then triangles with a "tile

clinker". That made cutting and breaking the strips much easier.

The center of the triangle was removed with my "ameritool"

saw. The corners were nipped off with a tile nipper. Then I grozed the

glass to smooth it further. No grinding. Then back into the kiln to

be fired again to 1440 with a 18 minute hold to round out the edges.

The big revelation for me this year was discovering that I could use

the tile clinker to cut and break glass. It has I

made a new sheet of glass by fusing a base Bullseye 3304. I think it

was curious. The tiny pieces of dichroic were added across the surface

with tweezers, some face up and some face down. Then strips of 1441-50

were placed on top. It was fused to about 1440 with a 22 minute hold.

After the first fusing, I cut strips and then triangles with a "tile

clinker". That made cutting and breaking the strips much easier.

The center of the triangle was removed with my "ameritool"

saw. The corners were nipped off with a tile nipper. Then I grozed the

glass to smooth it further. No grinding. Then back into the kiln to

be fired again to 1440 with a 18 minute hold to round out the edges.

The big revelation for me this year was discovering that I could use

the tile clinker to cut and break glass. It has

revolutionized how I cut thick glass.

|

| |

|

| |

#63: Michele Rubin

Screen-Printed

Orcas Screen-Printed

Orcas

1. Cut and full fuse 2 layers of glass for bases. I used black irid

for the back piece and plain black DR for the top. The irid back insures

that the glass will not pick up any kiln wash during the fusings.

2. For the orcas, I made a silk screen that had 30 design elements in

a 6 x 5 layout on a 12” x 12” screen. I cut BE red DR to fit

within the screen dimensions. Black Paradise paint mixed with A-13 was

used for the printing. After printing the sheets of design elements

were fused at 1425 deg for 10 mins to mature the printed images. I did

not do anything to avoid devitrification and was pleased not to have

that problem.

3. The design elements were cut into strips by hand and then the individual

elements were cut on the bandsaw.

4. The design elements were placed on the bases and tack fused at 1385

deg for 8 minutes.

|

| |

|

| |

#65 Debra Young

Made

7 casting molds for the faces Made

7 casting molds for the faces

Used hairspray or CMC (whichever was closest) mixed with opaque powder

frit for the details

The majority was backfilled with opaque powder frit and fired once

Lots of experiementing with frits and mica

Used 'Back Magic' on a few to get a luster like appearance

Some are unique and some are just plain homely but to say the least...no

two alike

Hope you enjoy them

|

| |

|

| |

#67 Susan Morita

|

| |

|

| |

#68 Loretta Brost

|

| |

|

| |

#69 Jeanette Bailor

Project

Mica Experimentation - something other than airbrushed mica. Project

Mica Experimentation - something other than airbrushed mica.

Bullseye glass.

Bottom layer Tekta, although a few of the mags have clear rainbow irid

for the base as I had a scrap.

Next layer, strips of 1426 Spring Green and 4200 Black Mardi Gras.

On top of that are small squares of 0100 black. On these small squares

I experimented with various micas. All my micas were mixed with Klyr

fire, just a drop from the end of a toothpick on the black glass seemed

to be adequate to bond

the micas. Part of the experiment was making some juicier than others.

Some had the mica smooshed on and left uncapped, lending a rough mica

texture. Some had the mica completely capped with clear and those ended

up with depth, like a small gold nugget under water. Some had the mica

capped with clear slightly smaller

than the black square and that allowed the mica to creep out and up,

creating a small mica cavern. I think those bits were the most interesting

and afforded the most diverse appearance of depth. I did a single full

fuse firing on these.

I made sure there were no sharp points on any of the mags (some of the

mags that were partially uncapped grew a little sharp pointy thing out

the top). I decided to scribble a little bit of gold accents on the mags

to see how that would go with the mica, using Hanovia gold. Lessons learned

– I do not like the effect of silver micas, capped or uncapped. The various

golds and russets are interesting, each has good points. I really like

the depth you can get by capping and allowing creep out of the mica during

firing. This was an interesting experiment and I will use what I learned.

|

| |

|

| |

#70 JJ Jacobs

The

result of waiting until it’s nearly too late, I quickly created

“Funky Town” out of various colors of Bullseye glass strips

and dichroic glass. In the beginning of this Magless adventure I attempted

to grind the bottoms of the little buildings to sit perfectly upon the

green strip of “grass” but due to time constraints quickly

gave up that idea and allowed the uneven bottoms to tilt where they

would, giving the towns their funky lop-sided look. Breaking the small

windows of dichroic glass was done by tapping the cuts with the ball

side of a tiny hammer and placing them on the buildings with tweezers.

I fired them in two different kilns to 1385 degrees. The

result of waiting until it’s nearly too late, I quickly created

“Funky Town” out of various colors of Bullseye glass strips

and dichroic glass. In the beginning of this Magless adventure I attempted

to grind the bottoms of the little buildings to sit perfectly upon the

green strip of “grass” but due to time constraints quickly

gave up that idea and allowed the uneven bottoms to tilt where they

would, giving the towns their funky lop-sided look. Breaking the small

windows of dichroic glass was done by tapping the cuts with the ball

side of a tiny hammer and placing them on the buildings with tweezers.

I fired them in two different kilns to 1385 degrees.

|

| |

|

| |

#71 Sandra McDonald

|

| |

|

| |

#72 Peggy Mattock

Method

and Madness Method

and Madness

Take a lot of 150cm long 6mm diameter Schott rods (optically clear coe

91 glass), and snip into bits using mosaic cutters. Rest aching hand

round cold glass of wine.For a week.

Arrange 19 rod bits end up into hexagons. To prevent insanity ponder

on the maths - to make a hexagon with sides of X rods you need (3 x

(X2 – X))+1 rods. That’s why I stopped at the size I did –

though one lucky maglesseer will get a mag the next

size up, made of 37 bits of rod. Using a straight edge push the rods

together on all sides to make sure they’re touching. Fire to 820

(Celsius), hold 10 min.

Plonk each resulting hexagon on a bit of CBS dichro (all but one on

black) and fire again to the same temperature. The second firing softens

and rounds the rods much more than the first. Some mags got fired a

bit hotter, and are more rounded off than others. Some opened up like

flowers (OK, the edges sort of collapsed outwards).

Rinse and repeat.

Lessons Learned

Rods roll. Arranging the hexagons was a nightmare – and carrying

the shelf to the kiln very precarious. They look best when there are

widely varying lengths of rod - the clarity of the glass enhances the

dichro – you get flashes of colour at the rod ends when your perspective

changes. Unless you got one of the dark blue ones,

which aren’t as sparkly.

If your mag broke in transit fire as per Bullseye, a bit cooler than

usual at the top temperature and anneal a bit hotter, though at that

size I doubt it really matters.

|

| |

|

| |

#73 Matthew Lovein

|

| |

|

| |

#74 Jenefer Ham

|

| |

|

| |

#75 Amy Valuck

|

| |

|

| |

#76 Pam Damon

There

are few variations on the "stamping with mica" theme All were

made with Bullseye glass and mica. There

are few variations on the "stamping with mica" theme All were

made with Bullseye glass and mica.

A piece of clear was stamped using Perfect Medium by Ranger, then sprinkling

mica this became the top glass.

The "star dust" magless was made with a star stamp: yellow

frit on clear glass topped with clear glass stamped with mica.

The "heart strings" was made with a heart stamp: pink or red

stringers on clear glass topped with clear stamped with mica.

The "hearts and stars" was made with a heart stamp: precut

star(s) on clear glass topped with clear glass stamped with mica.

The Kokopelli was made with a Kokopelli stamp: a precut star on clear

glass topped with clear glass stamped with mica.

What I learned was get started earlier I would have liked to do some

grinding and polish fusing but didn't have time, and use a stamp that

covers more area for a more defined look.

"star dust" I liked the looks

"heart strings" The stamp was lost in the strings

"hearts and stars" The precut stars retain their shape with

full fuse between two layers

"Kokopelli" I liked the look

|

| |

|

| |

#77 Susan Hutsko

How

To For: How

To For:

Bobbi’s Sun Dancers

Glass used – Bullseye

French vanilla

Tetka

Mint green powder

Red powder

Black powder

Process

1. Make stencils for background wafers and sun dancers.

2. Prepare powder wafers - 126 background and 126 sun dancers. Firing

schedule – 600 degrees per hour to 1285, hold 10 minutes

3. Fuse French vanilla and tetka

4. Cut french vanilla/tetka sheet into 1 ½ inch squares with

band saw.

5. Grind edges as needed.

6. Place one background wafer and one sun dancer on each square and

fire.

Firing schedule:

Seg 1 400 hr to 1100 hold 15 minute

Seg 2 400 hr to 1425 hold 1 minute

Seg 3 9999 to 1100 hold 15 minute

Seg 4 100 hr to 960 hold 45 minutes

Seg 5 100 hr to 700 hold 1 minute

|

| |

|

| |

#79 Deb Compton

First

a disclaimer: Everything I’ve learned, I’ve learned from

the board! This site was the most helpful for pot melts: First

a disclaimer: Everything I’ve learned, I’ve learned from

the board! This site was the most helpful for pot melts:

http://www.clearwaterglass.com/aperture_pour_test.htm.

Not all my photos or magless’ are from the same pot melt.

How To:

1. Load a flower pot with compatible glass. (Don’t put kiln wash

in the flower pot.) I didn’t enlarge the hole but you certainly

can.

This is how one of mine looked.

2. Prep the saucer with kiln wash. Set it up in the kiln so the glass

drips out onto the saucer. If you want the colors to remain separate,

I’ve found it helpful to keep

the flower pots close to the saucer. If you want the rings and a more

blended pot melt you can lift the saucer up.

3. Fire away!

1000 dph to 1700F, hold 60 min.,

AFAP to 1500F, hold 45 min.

AFAP to 960F hold 60 min

200 dph to 750F300 dph to 300F

Off

4. My pot melts came out with a “belly button,” probably

because I didn’t hold

long enough. (I consider it a happy accident.) To get rid of the belly

button I

put them back I the kiln with the next pot melt run and the result is

what looks

to be a combo “pot melt/high fire.” See below.

See how the orange comes to the surface? I think it’s more dramatic

after the second firing.

4. I cut the pot melts with the tile saw into sizes appropriate for

the magless. (The tile saw was plenty wet but I made sure that I kept

the pieces wet by immediately putting them in a bowl of water-I was

hoping to prevent grinder scum. Another tip from the board!) When they

were all cut I washed them with soap and water (“That product called

Dawn”), giving the edges an extra scrub.

5. I fired them once more to a full fuse-1480 degrees, annealed as

usual and “wala,” I present my 2006 magless!

Enjoy!

|

| |

|

Now

that all my glass emissaries have been labeled, bagged, boxed and shipped

all the things that I would have, could have and should have done to

make them better come to mind. They will be strewn all over the country,

well the world for that matter, conjure them perfect I would; but the

deadline for their transport had arrived, and I have no more time to

give them. So I send my ambassadors off into this world

Now

that all my glass emissaries have been labeled, bagged, boxed and shipped

all the things that I would have, could have and should have done to

make them better come to mind. They will be strewn all over the country,

well the world for that matter, conjure them perfect I would; but the

deadline for their transport had arrived, and I have no more time to

give them. So I send my ambassadors off into this world Introduction:

Introduction: Glass

log: Jan.07, 2006

Glass

log: Jan.07, 2006

Glass

log: January 10, 2006.

Glass

log: January 10, 2006. Glass

log: 1/17/06

Glass

log: 1/17/06

After

firing the color of the copper wire varies from white to copper to black;

whatever was used to tin coat that wire is giving some odd results,

there is a remote possibility that it is a metal other than copper.

After

firing the color of the copper wire varies from white to copper to black;

whatever was used to tin coat that wire is giving some odd results,

there is a remote possibility that it is a metal other than copper.

Glass

log: January 22, 2006

Glass

log: January 22, 2006

Luckily

the rock tumbler was on sale, only 20 bucks! An artist friend loaned

me her tumbler, which hadn't been used for 20 years; but it had all

the carbide grits with it. The loan tumbler was a much better make than

the Chinese one that I bought. Between the two tumblers I was able to

get 50 of them ground off and fire polished. They're bit of all right!

My Chinese rock tumbler has busted to drive belts, and is now out of

commission while the 20- year-old American-made one is still going strong.

Luckily

the rock tumbler was on sale, only 20 bucks! An artist friend loaned

me her tumbler, which hadn't been used for 20 years; but it had all

the carbide grits with it. The loan tumbler was a much better make than

the Chinese one that I bought. Between the two tumblers I was able to

get 50 of them ground off and fire polished. They're bit of all right!

My Chinese rock tumbler has busted to drive belts, and is now out of

commission while the 20- year-old American-made one is still going strong.

What

I learned:

What

I learned: Ok,

from the beginning, I took a class with Brad Walker a few months ago,

and one of the things I brought for an experiment was some brass steel

woolish stuff. Made by Mr. Clean, If you are careful, you can punch

out one end, and un-crochet it. If you roll it out, it looks like chain-maille

(not sure if that is the word, think of jousting in Medieval times and

the stuff that covered their arms).

Ok,

from the beginning, I took a class with Brad Walker a few months ago,

and one of the things I brought for an experiment was some brass steel

woolish stuff. Made by Mr. Clean, If you are careful, you can punch

out one end, and un-crochet it. If you roll it out, it looks like chain-maille

(not sure if that is the word, think of jousting in Medieval times and

the stuff that covered their arms).

How-to

for "Dichroic Flats"

How-to

for "Dichroic Flats" My

maglesses are miniature pot melts done in very tiny clay pots. The glass

I used was about ¾ clear mixed with yellow, adventurine green,

and cobalt (I think) blue. I enlarged the holes on the pots and stacked

the glass inside horizontally. Fired to 1700 degrees for 30 minutes.

I was able to fire about 10 at a time and I was able to keep reusing

the pots. I hope you enjoy

My

maglesses are miniature pot melts done in very tiny clay pots. The glass

I used was about ¾ clear mixed with yellow, adventurine green,

and cobalt (I think) blue. I enlarged the holes on the pots and stacked

the glass inside horizontally. Fired to 1700 degrees for 30 minutes.

I was able to fire about 10 at a time and I was able to keep reusing

the pots. I hope you enjoy My

magless is a 1.5" square of bullseye opal (many are curious colors)

topped by a 1" square of white. The white square was sprinkled

with Thompson enamels then covered with clear frit. All was brought

to a full fuse. What really surprised me was how much difference there

was in how the different colored bases "beaded up" -- I know

different colors absorb heat differently, but I was surprised by just

how much! The steel blue pieces fused so much they were almost more

round than square while the red and powder blue pieces were closer to

tack fused than full. (I re-fused the tack fused pieces so they would

flatten out more.) I also learned that I can only do one full fuse with

opals on a shelf before changing the kiln wash -- one whole batch came

out with needling and rough edges when I tried to get a second firing

on one shelf.

My

magless is a 1.5" square of bullseye opal (many are curious colors)

topped by a 1" square of white. The white square was sprinkled

with Thompson enamels then covered with clear frit. All was brought

to a full fuse. What really surprised me was how much difference there

was in how the different colored bases "beaded up" -- I know

different colors absorb heat differently, but I was surprised by just

how much! The steel blue pieces fused so much they were almost more

round than square while the red and powder blue pieces were closer to

tack fused than full. (I re-fused the tack fused pieces so they would

flatten out more.) I also learned that I can only do one full fuse with

opals on a shelf before changing the kiln wash -- one whole batch came

out with needling and rough edges when I tried to get a second firing

on one shelf. I

started trying to cut out strips that were straight enough to fuse together.

I soon realized this was going to be a big job. I had a "Silberschnitt

Roll up pad with parallel cutter" that I hadn't used but a couple

times. I got it out and that was the answer. You can cut straight thin

strips that are very accurate. I cut out strips of all colors of opaque

90COE BE glass. I used BE opaque white for the

I

started trying to cut out strips that were straight enough to fuse together.

I soon realized this was going to be a big job. I had a "Silberschnitt

Roll up pad with parallel cutter" that I hadn't used but a couple

times. I got it out and that was the answer. You can cut straight thin

strips that are very accurate. I cut out strips of all colors of opaque

90COE BE glass. I used BE opaque white for the Little

Keyboards

Little

Keyboards Mine

were pretty simple - I was initially inspired by African Kiffa beads.

In Northwest Africa, women grind bottles to make powder, make a paste

with gum arabic and/or spit, and then make beads decorated with intricate

patterns of powdered glass. The beads are then fused on sand in a can

on top of a charcoal fire. (See

Mine

were pretty simple - I was initially inspired by African Kiffa beads.

In Northwest Africa, women grind bottles to make powder, make a paste

with gum arabic and/or spit, and then make beads decorated with intricate

patterns of powdered glass. The beads are then fused on sand in a can

on top of a charcoal fire. (See  I

decided to combine two techniques with my mags. Copper inclusions &

powdered frit stenciling. My magless’s consists of 2 layers of

Bullseye 90 COE glass. The base glass is white & the top glass is

clear. I was going for a look of depth with the moose behind the tree.

I

decided to combine two techniques with my mags. Copper inclusions &

powdered frit stenciling. My magless’s consists of 2 layers of

Bullseye 90 COE glass. The base glass is white & the top glass is

clear. I was going for a look of depth with the moose behind the tree.

First

I would like to thank Brad for providing the Warmglass board and the

Warm Tips Section, which gives me the opportunity to learn everyday

about glass without having to travel and take classes.

First

I would like to thank Brad for providing the Warmglass board and the

Warm Tips Section, which gives me the opportunity to learn everyday

about glass without having to travel and take classes.

I

made a new sheet of glass by fusing a base Bullseye 3304. I think it

was curious. The tiny pieces of dichroic were added across the surface

with tweezers, some face up and some face down. Then strips of 1441-50

were placed on top. It was fused to about 1440 with a 22 minute hold.

After the first fusing, I cut strips and then triangles with a "tile

clinker". That made cutting and breaking the strips much easier.

The center of the triangle was removed with my "ameritool"

saw. The corners were nipped off with a tile nipper. Then I grozed the

glass to smooth it further. No grinding. Then back into the kiln to

be fired again to 1440 with a 18 minute hold to round out the edges.

The big revelation for me this year was discovering that I could use

the tile clinker to cut and break glass. It has

I

made a new sheet of glass by fusing a base Bullseye 3304. I think it

was curious. The tiny pieces of dichroic were added across the surface

with tweezers, some face up and some face down. Then strips of 1441-50

were placed on top. It was fused to about 1440 with a 22 minute hold.

After the first fusing, I cut strips and then triangles with a "tile

clinker". That made cutting and breaking the strips much easier.

The center of the triangle was removed with my "ameritool"

saw. The corners were nipped off with a tile nipper. Then I grozed the

glass to smooth it further. No grinding. Then back into the kiln to

be fired again to 1440 with a 18 minute hold to round out the edges.

The big revelation for me this year was discovering that I could use

the tile clinker to cut and break glass. It has Screen-Printed

Orcas

Screen-Printed

Orcas Made

7 casting molds for the faces

Made

7 casting molds for the faces

Project

Mica Experimentation - something other than airbrushed mica.

Project

Mica Experimentation - something other than airbrushed mica.  The

result of waiting until it’s nearly too late, I quickly created

“Funky Town” out of various colors of Bullseye glass strips

and dichroic glass. In the beginning of this Magless adventure I attempted

to grind the bottoms of the little buildings to sit perfectly upon the

green strip of “grass” but due to time constraints quickly

gave up that idea and allowed the uneven bottoms to tilt where they

would, giving the towns their funky lop-sided look. Breaking the small

windows of dichroic glass was done by tapping the cuts with the ball

side of a tiny hammer and placing them on the buildings with tweezers.

I fired them in two different kilns to 1385 degrees.

The

result of waiting until it’s nearly too late, I quickly created

“Funky Town” out of various colors of Bullseye glass strips

and dichroic glass. In the beginning of this Magless adventure I attempted

to grind the bottoms of the little buildings to sit perfectly upon the

green strip of “grass” but due to time constraints quickly

gave up that idea and allowed the uneven bottoms to tilt where they

would, giving the towns their funky lop-sided look. Breaking the small

windows of dichroic glass was done by tapping the cuts with the ball

side of a tiny hammer and placing them on the buildings with tweezers.

I fired them in two different kilns to 1385 degrees.

Method

and Madness

Method

and Madness

There

are few variations on the "stamping with mica" theme All were

made with Bullseye glass and mica.

There

are few variations on the "stamping with mica" theme All were

made with Bullseye glass and mica. How

To For:

How

To For: First

a disclaimer: Everything I’ve learned, I’ve learned from

the board! This site was the most helpful for pot melts:

First

a disclaimer: Everything I’ve learned, I’ve learned from

the board! This site was the most helpful for pot melts: